How to Clean & Maintain Anilox Rolls

First published in FLEXO Magazine, August 2016 issue.

Written by Harper Southeast HGS advisor, Greg Harms

Anilox roll cleanliness is arguably one of the most important considerations in flexographic printing. A dirty anilox roll will reduce its effective volume, resulting in weak printed colors. In turn, this is the root cause for a barrage of issues that includes ghosting, dirty print, color match problems and, ultimately, press downtime.

Dirty anilox rolls correspondingly have a substantial negative impact on repeatability. Improper cleaning techniques, lack of training, improper use of cleaners/cleaning devices and a disregard of attention to detail all attribute to poor anilox roll care, resulting in headaches on press and a loss of potential revenue.

An understanding of anilox cell size is critical to understanding proper cleaning procedures. An anilox’s cells are extremely small. For example, the opening on a 1,200 cpi anilox roll is only 18-µ. the opening on a 600 is 38-µ. To put this into perspective, a human hair is 100-µ. wide. The cells are a fraction of a human hair, and it doesn’t take much to plug them up. To assure these microscopic cells are kept clean, proper cleaning methodologies need to be followed.

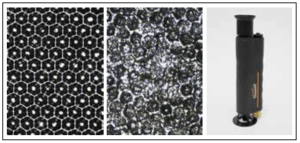

A baseline understanding of what it means to actually clean an anilox roll is essential. Just because you wipe down a roll does not mean it is truly “clean.” I am a firm believer in the “prove it” methodology— Prove to me the roll is clean. This can be easily accomplished using a microscope to look at the cells. Image 1 depicts two states; one shows clean cells, the other plugged cells. The key identifier of a clean cell is the white dot in the center. The white dot is the light reflecting back from the bottom of the cell. If you do not see this dot, it means the bottom of the cell is plugged with ink.

The key identifier of a clean cell is the white dot in the center. The white dot is the light reflecting back from the bottom of the cell. If you do not see this dot, it means the bottom of the cell is plugged with ink.

CLEANING BASICS

One of the most basic yet important concepts when cleaning the anilox roll is to do so as soon as possible. Letting the rolls sit in the press, not rotating or without a supply of ink, will cause that ink to dry in the cells. To prevent this, keep the ink and rolls circulating. This will keep the ink wet and make it much easier to clean up. Remember how small the cells are: It does not take long for the ink to dry. The level of cleaning difficulty increases exponentially as the ink dries or cures in the cells.

Handle your anilox rolls with care. The anilox rolls are typically safest in the press and the most damage occurs when they are moved. Keeping the rolls covered will decrease this risk. Use two hands to carry the anilox rolls to assure you have a solid grip. Do not lift the rolls by the gears or bearings. I have seen operators do this with the set screw loose and the anilox roll bounced on the floor. I am sure their supervisor wasn’t too happy about this. Also, do not carry anilox rolls over your shoulder. They are not properly supported and an increase in damage is likely.

Ceramic is hard, but any major impact can damage a roll. If it isn’t outright chipped or damaged, it more than likely will develop small cracks. These cracks allow cleaners to migrate under the ceramic and will grow over time, creating even more issues. Keep metal objects like Allen wrenches, screwdrivers and ink knives away. If an anilox is set on a table, make sure it is clean and free of debris; I recommend setting the anilox roll on a bed of towels or a stand that keeps the engraving surface from touching anything. And don’t drag a roll across countertops or other surfaces, as it is likely to be scratched.

Using a handheld scope can visualize the difference between clean and plugged cells. Photos courtesy of Harper Corporation of America

Don’t forget to clean the ends of the rolls. The ends of the rolls are commonly overlooked when cleaning, especially with UV ink. One spot of UV ink can spread to the face of the roll in a hurry. Many times, ink will build up on the ends of the roll, especially after long runs. Operators will commonly use a metal paint scraper or screwdrivers to remove this dried ink. This is not a recommended practice. Use a plastic scraper instead of metal. The likelihood of damaging the roll is far less with plastic than it is with metal.

Using the proper cleaning apparatuses and solutions can make a world of difference in maintaining an anilox roll.

Unquestionably, the most overlooked step when cleaning anilox rolls is rinsing and drying. Rinsing the rolls will remove any cleaner that may be left and eliminates the possibility of it causing corrosive damage. It also assures the ink debris is flushed away, leaving a roll that is actually clean. Failure to dry the roll will cause water spots. Sadly, this is a common occurrence in many pressrooms and can show up in print. Water spots can be easily avoided by rinsing and drying rolls after cleaning. A 50/50 mix of isopropyl alcohol and water will aid in rinsing and drying. Make sure to completely dry a roll before applying its cover. Failure to do to so will trap any solvents or liquids on the surface. They can then migrate to the base metal and cause issues as well as a camouflaging pattern.

RAGS & BRUSHES

There are many different products that can be used to clean an anilox roll. The most common is a shop rag. But shop rags can contain metal fragments they picked up in a previous life at a manufacturing facility or machine shop. They are then spun clean and sent to their next location. Because of this, it is highly recommended to use metal free rags. Although they may cost a bit more, it is well worth it.

Another common tool for cleaning is a microfiber sponge. These can work great to mold to the contours of the roll and their flexible nature allows them to really get into the cells.

Under no circumstances is it OK to clean an anilox with abrasive pads. They go by many names:

• SOS pads

• Steel wool

• Green abrasive pads

• White abrasive pads

Any type of abrasive pad will polish down the engraving, reducing the roll’s volume and life.

On the flip side, it is OK to use an approved stainless steel cleaning brush. This is not an invitation to go to Home Depot or Lowe’s and purchase a barbecue cleaning brush; that’s not the proper type of metal and it will damage your anilox roll. Stainless steel anilox roll cleaning brushes have a metal that is softer than the ceramic and therefore will not damage the roll. It is important to note there are also brass brushes that are not to be used with ceramic rolls—they are made for chrome aniloxes. The stainless steel brushes should not be used on chrome rolls either, as it will scratch them.

Prove the roll is clean by looking “ at the cells with a microscope and then you can stop cleaning.

The bristles on an anilox roll brush are larger than the opening of most cells and therefore will not fit inside them. The cleaning magic happens when you use the brush and an appropriate cleaner in a circular motion. This action pushes the cleaner into the cells and helps pull the ink out.

I am always asked, “How long do I need to scrub the anilox roll?” My answer is simple: Until the roll is clean. There is no magic number of circles or a set time. Prove the roll is clean by looking at the cells with a microscope and then you can stop cleaning.

LIQUID CLEANERS

Every plant is using a different cleaner and there are thousands of options out there. Some are effective and some will damage your rolls. I recommend referring to your anilox roll experts on what to use.

Be cautious when using corrosive cleaners. The pH range for cleaners used on an anilox roll should be between 5.5 and 11.5. Any cleaner outside this range is likely to damage the roll. I will note that some cleaning systems use corrosive cleaners to aid in the cleaning. This type of system minimizes the time the cleaner is in contact with the roll, as they are then rinsed thoroughly.

With a lengthy exposure time, chemicals can migrate through the roll to the base material. As we discussed, damage and cracks make this migration even easier. If the chemicals are outside of the acceptable pH range, they can cause the ceramic to blister; delamination of the ceramic could also occur. This will not happen overnight and can be prevented by using the proper cleaners.

Most anilox roll bases are made from mild steel, but many sleeves and some lightweight rolls are made with aluminum. Some cleaners will attack and corrode aluminum, and should obviously be avoided if you have rolls made from that material.

STORAGE & SHIELDING

Protect your anilox roll investment by storing them properly. Keep in mind that dragging a roll on anything increases the likelihood of scratches to its face. Dried ink is extremely hard and will damage a roll. If it is on covers or storage shelves, it will increase the likelihood of damage. Consider ergonomics to aid in a storage system’s ease of use. Design an area that is easy to access and has sufficient room to remove the rolls without them contacting or bumping into each other.

Shield your anilox rolls by covering them. Covers work great, but only when they are actually covering the roll. Having them sit in a drawer or on the floor will do you no good. The cleanliness of a roll cover is also important, particularly with UV inks, where the ink can spread when not cured.

WATER BASED INK CLEANING TIPS

One of the most common mistakes made when cleaning water based ink is using just H2 O. Operators may pull the anilox rolls and bring them directly to the sink to be cleaned with only water.

Do not fall into the misconception that if two points higher is good, then four must be awesome. This is just not true; in fact, it is worse.

Water based ink has a pH of approximately 8.5-9.5, depending on the ink system. This pH level keeps the pigment particles suspended and the ink functioning properly. Water has a pH of about 7 and when used to clean up anilox rolls, it drops the pH of the ink it contacts. This shocks the ink, throwing it out of balance and making it more difficult to clean up. It can even lock the ink in the bottom of cells and reduce the roll’s volume.

To aid in the cleaning up of water based ink, a cleaning solution with a pH of two points higher than the ink is recommended. This pH level helps to re solubilize the ink and makes clean up remarkably easier. Please note: The maximum acceptable pH level of roll cleaners is 11.8 and exceeding that allows for potential damage to the anilox. Do not fall into the misconception that if two points higher is good, then four must be awesome. This is just not true; in fact, it is worse.

Another abused technique is the use of soak tanks. To increase productivity during changeovers, the operators will pull the rolls out of press and put them in a soak tank. The aniloxes sit in the tanks until they are cleaned. The theory behind this is that by soaking the rolls, it prevents the ink from drying. This is not a good practice and I do not recommend it.

Why? The mystery solution in the tanks is usually just water and as we discussed, this is not a good cleanup solution. If the pH of the solution is high, it can damage the rolls, especially if they are soaking for a while. This allows the cleaner to work its way through the ceramic to the base metal of the roll. Many times, these soak tanks are used for more than one ink chemistry and that only complicates the issue. Different ink chemistries typically do not mix well and can cause a cleaning nightmare by locking up the inks in the cells or creating residues that are almost impossible to remove.

More often than not, these soak tanks are not cleaned on a regular basis. The solution on the inside looks like sewage with floating debris. To make matters worse, the tanks are usually lined with dried ink. Dried ink is extremely hard and if an anilox is rubbed against it, the potential for a scratch is high. The use of soak tanks typically means the gears and bearing of the rolls are being submerged in water or cleaner. It is never a good idea to submerge gears and bearings—It will only cause them to fail sooner.

UV BASED INK CLEANING TIPS

UV ink is cured, not dried. This curing process is started by exciting the photoinitiators in the ink with intense UV lights at a specific wavelength.

Some shops will pull their anilox rolls out of the press and let them sit under shop lights. The lighting in your shop—whether it is fluorescent or incandescent—contains stray UV energy to initiate the crosslinking process of the photoinitiators. Granted, it is not as intense as the bulbs used in press, but it will begin to cure the ink. The longer you leave the rolls exposed to the light, the more the ink will cure. The ink will not cure overnight, but over time you will see a reduction in volume. Once the ink is cured in the cells, it becomes difficult to remove it. I always recommend thoroughly cleaning the rolls if they are not going to be used. At the very least, cover the rolls to prevent the UV rays from reaching the ink.

When cleaning UV ink, it is also important to select a cleaner that is formulated to break the ink down. I stay away from fast solvents for cleaning, because they tend to cause more issues. Many UV cleaners are a slow solvent, so they can get in and break down the ink. The slow solvents do not evaporate quickly, so it is critical to rinse them using an alcohol or a fast solvent.

Granted, it is not as intense as the bulbs used in press, but it will begin to cure the ink. The longer you leave the rolls exposed to the light, the more the ink will cure.

OFF PRESS CLEANING

It is of paramount importance to keep anilox rolls clean. There are many off press cleaning systems that work well; however, be sure to follow the OEM’s specs. Increasing pressures or temperatures outside the recommendation can damage the roll.

If using ultrasonic cleaners, keep in mind the soak and ultrasonic times. Operators like to put the anilox rolls in with the ultrasonic on for much longer than recommended. With ultrasonic cleaning, the rotational soaking time is important. If a roll is not getting clean when adhering to OEM specs, something within the system is not functioning properly and I would recommend contacting the supplier.

If you inspect your anilox rolls and the cells are plugged, there are two things you need to do:

• Thoroughly clean the rolls (in an appropriate fashion) to get all of the dried ink out and restore the cells to their original condition. This is where many people go wrong. In a panic, they attempt to free up the cells with abrasive devices, or soaking with corrosive cleaners. In the end, they only end up damaging the rolls and causing thousands of dollars of irreparable damage. I can’t stress it enough: If you are unsure of how to clean your anilox rolls, ask questions. It could save you thousands of dollars

• Once the rolls are clean, put in place a cleaning process to maintain them. One of the most challenging things to accomplish is changing the process after people have been doing it a certain way for years. Take the time to properly train and explain to your employees the new process. All too often, companies have good intentions; however, the new process is not fully explained. Questions are not answered and they wind up in the same spot they were before

The No. 1 thing any printer can do is properly train employees. I find that lack of training is the single greatest cause of mistakes at print shops. Take the time to educate your employees on the importance of proper care and maintenance of anilox rolls. It is a small investment of time that will decrease damage and increase repeatability, consistency, and ultimately your customer satisfaction.

About the Author: Greg Harms has amassed more than 20 years of experience in production and management throughout the flexographic industry. Greg joined Harper in May 2012 as the Southeast HGS advisor and currently holds the position of technical account manager for narrow web in the Great Lakes region. Prior to joining Harper, Greg was the operations manager at St. Louis Pressure Sensitive. As operations manager, he focused on team building, lean manufacturing and cost reduction.

To view the original FLEXO Magazine article click HERE.