The XLT was developed for precisely transferring ink with micron accuracy. We recommend and guarantee that when you work with the strongest, thinnest film of ink, you will get the best ink mileage, best print quality, easiest impression set-up, and you’ll get it at the most consistent levels possible.

APPLICATIONS

SPECIFICATION RANGE

- Process

- Expanded Gamut

- PMS

- Solid

- Combination

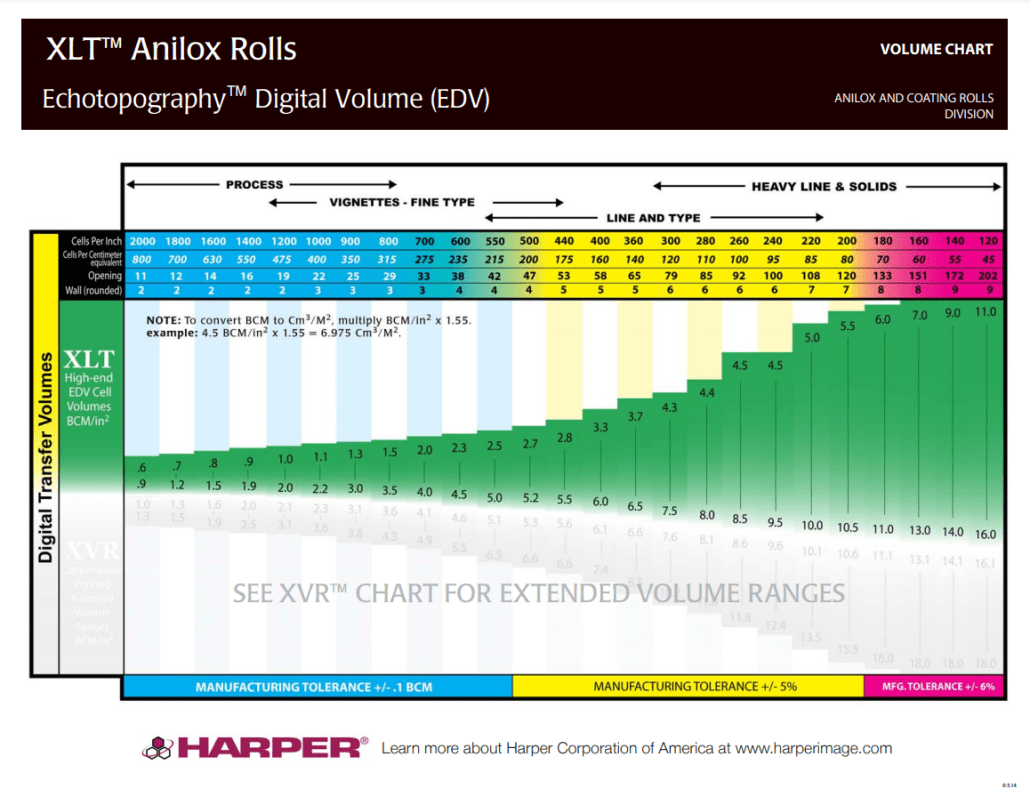

Volume: .6-18 BCM

Line Screen: 120-2000 CPI

- Low porosity <1%

- RA < 3 prior to engraving

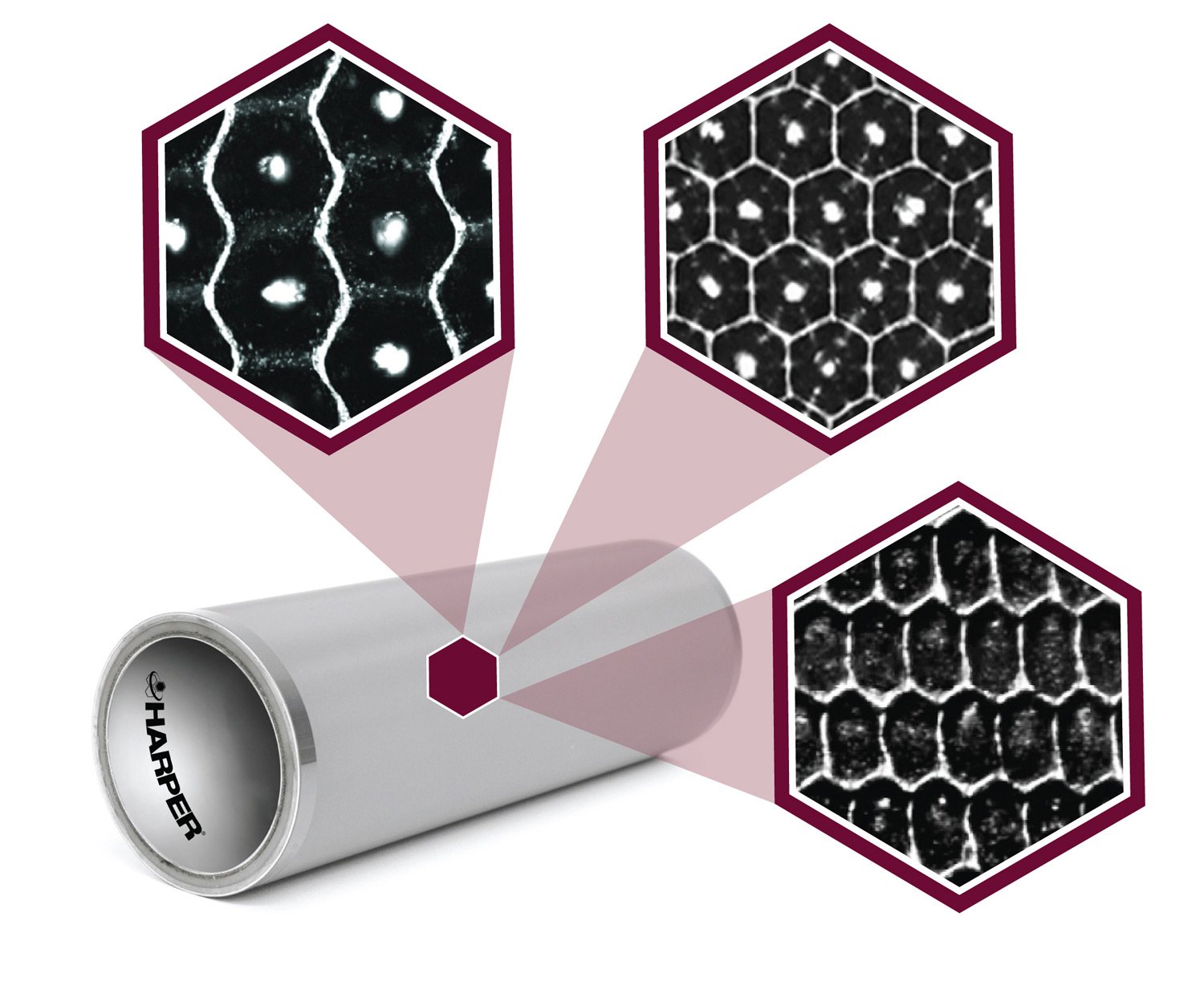

Cells to Polymer Dot Ratio

When calculating the proper ratio of cells per inch to support your minimum desired polymer dot, remember the 6:1 ratio. A 2% Dot requires 900 cells per inch to maintain 150 line per inch printing. This ratio minimizes overloading the smallest dot with too much ink which would result in dot bridging and a perceived “dirty print”.

Recommended Geometry:

- 30º Hex

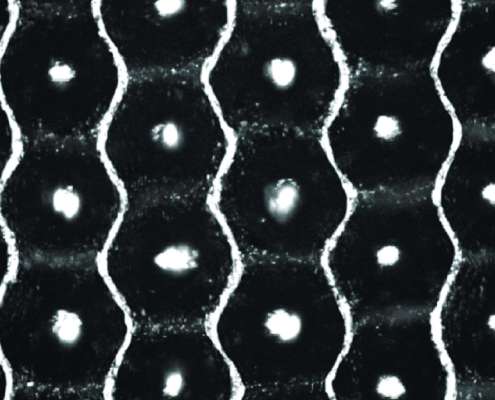

- 30º Hex Channel – for White & UV Heavy Ink Coatings Decorative Technologies

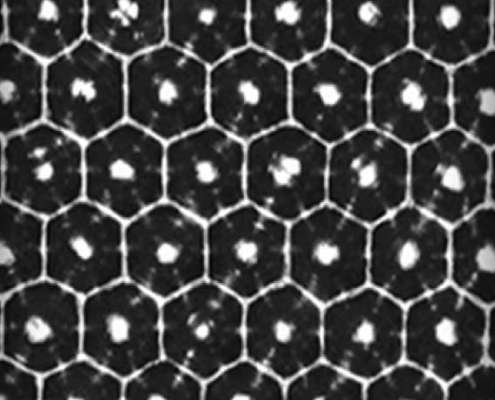

- 60º Hex – for Print

Other Geometries Available:

- 70º Hex – for Heavy Coatings / may reduce foaming

- 45º Quad

- 45º TriHelical

- 89º TriHelical

QUALITY + WARRANTY

Harper has taken great pride in ensuring every customer experiences ‘print quality’ improvements as a result of delivering excellence in its products and services. Experience greater peace of mind with the fairest, most comprehensive warranty in the industry.

RECOMMENDED GEOMETRY

HEX

TRADITIONAL CHANNEL

QUAD

TRIHELICAL

DIGITAL TECHNOLOGY

Harper’s XLT Digital Engraving Technology delivers the best of both worlds: greater volume and better transferability. The new cell profile enables the digital engraving of aniloxes at higher cells per inch with greater volumes. The results when combined with the ongoing technological advancement in the Flexographic industry is unprecedented graphic fidelity.

Ready to get started? Contact the Harper team first and we’ll assist you every step of the way.

PRODUCTS YOU MAY BE INTERESTED IN…

From the advent of flexographic printing and Anilox Roll manufacturing, Harper Corporation of America has earned the distinction of being the best, and the global leader in new anilox roll products and technologies. We offer more than our word. Every claim Harper makes about our products, services and support is backed by the best warranty in the industry.

From the advent of flexographic printing and Anilox Roll manufacturing, Harper Corporation of America has earned the distinction of being the best, and the global leader in new anilox roll products and technologies. We offer more than our word. Every claim Harper makes about our products, services and support is backed by the best warranty in the industry.

Harperscientific™ is the Printing and Coatings Supplies Division that provides products and services to flexographic printers all over the world. As a leader in the precision proofing market, HarperScientific supplies precision proofers, safe and user-friendly ink cleaners and measurement equipment.

Harperscientific™ is the Printing and Coatings Supplies Division that provides products and services to flexographic printers all over the world. As a leader in the precision proofing market, HarperScientific supplies precision proofers, safe and user-friendly ink cleaners and measurement equipment.

To deliver measurable and quantifiable solutions that keep your print room running at peak efficiency, Harper assembled a multi-disciplined team of expert, tools, systems and training to form Harper Technical Solutions. Our programs are customized, deliver a typical 6 month return on investment and are backed by the best warranty in the industry.

To deliver measurable and quantifiable solutions that keep your print room running at peak efficiency, Harper assembled a multi-disciplined team of expert, tools, systems and training to form Harper Technical Solutions. Our programs are customized, deliver a typical 6 month return on investment and are backed by the best warranty in the industry.