First published in Coating International, 2015 issue.

Written by Harper Product Development Engineer, Tony Donato

There have been a number of articles written on the upcoming revolution of printed functional devices and intelligent packaging. From working with a number of Universities as well as internal testing over the past 5 years I would like to address some of the challenges and possible solutions when trying to print these products roll to roll. I am not going to describe how the print transistors and other multilayer products work but I will state where we are today and what needs to be understood when attempting printing in a roll-to-roll process.

Around 10 years ago, Printed Electronics became the hot topic for futurists, innovators and venture capitalists. There are many examples of successes and failures but, as with motor racing, the old saying «the best way to end up with a small fortune is to start off with a large fortune» has been truthful in both fields. All of the money spent has not necessarily made the investors more money. But, it has helped to move the industry toward the dreams of the futurist.

Printing Electronics

Defining printed electronics has almost become an industry in itself. I will use a definition of «conductor traces, semi-conductors, insulators and or compounds applied in single or multiple layers applied to a substrate flexible or rigid that react or are stimulated with electrical current, gases, chemicals or temperature.» With that said, we need to look at the early days of electronics when the circuit boards were chemically etched and not start off by looking at nanometre dimensioned components of today that are made in cleanrooms in a very efficient method and which have proven to be extremely reliable.

Print Applications

Over the past 20 years, circuits and simple devices have moved into the flat screen-printing process. This process has been used and will continue to be very successful for designs where the trace line widths and thicknesses provide an economic way to produce reliable printed components and devices. All current trends indicate that flat screen-printing will continue to fill the need for my definition. But, as inks and applied materials keep improving to the point that they can provide the same functional performance with a narrower and thinner deposit, roll-to-roll processes like Flexography and Rotogravure are being seen as the processes that can be used to produce products in an economical manner.

When it comes to ink film thickness produced from the various processes used in graphic printing, digital printing typically yields the thinnest film followed, in order, by offset lithography, flexography, gravure, and screen. I believe, as do many, that Flexo and Gravure can be investigated as the replacement for flat screen printing when the demand for products increases and for products being designed where the printed circuits and layers can be combined into what is being call hybrid assemblies. A traditional nano dimensioned switching device (chip) can be assembled into printed portion to complete the device.

Printers need to think about the basics of functional printing. In graphic printing, Flexo & Gravure can place colored dots in a way to trick the human brain into thinking the eye is seeing continuous images as seen in nature. This type of printing can be done very fast, anywhere from 500 to 2000 fpm (150 to 600 mpm). In printing functional devices, we have to first understand that printed inks have to perform under the laws of electrical physics so currents can flow. Overly simplified, «electrons cannot jump» (at the required low voltages) from dot to dot. So, an incomplete printed trace line of ink will not be acceptable.

In moving from flat screen-printing to a R2R (roll-to-roll) process, R2R can be accomplished at very fast speeds. The issue with press speeds today is that we can print graphics extremely fast (500 fpm (150 mpm) narrow web and 2000 fpm (600 mpm) wide web.) But, that also means scrap can be printed extremely fast. For all practical purposes, with exceptions like glucose strips, the number of needed electronics related printed products required for a given batch size, can be accomplished at press speeds in the 50 to 150 fpm (15 to 46 mpm) range to help control print consistency and quality. Currently there is no need for speed at 500 fpm (150 mpm). The functional printed components need to meet a reliability and reject standard far beyond what is required for packaging. Again, we are dealing with electrical physics and not just tricking the human brain with information. That means one of the important issues is how to measure and inspect the printed products. This is one of the many challenges we face in the PE industry.

Ink Selection

The cost of the inks involved can be very expensive and in many cases hazardous. So the obstacles start with the amount of ink needed to start the process. A 5-gallon (20 litre) sump with nano silvers inks costing as much as $1,000/litre is out of the question. The innovative experimenters have been creating micro chambers to hold just enough ink to wet the anilox roll or gravure cylinder. In handling these inks, we also have to explore the reality of handling inks that have particles so small they can be absorbed through the skin into the human body. So, the inks create the challenge of controlling the ink usage and the handling of additional hazardous waste from all clean-up steps.Since more inks are moving to water based, we can look at the electroplating industry where, for years, they have had to develop metal recovery systems to pull all the precious metals from the liquid waste streams. Maybe laundry equipment needs to be made to pull the metals from towels. From the beginning, ink application and handling, waste clean-up, and recovery of materials from rejected printed batches need to be considered.

The ink developers are challenged to find materials that will give the electro and chemical properties and keep the costs down. This is not the only challenge for the ink companies. They also need an ink that allows enough levelling to complete the circuits while, at the same time, keeping the deposit thickness where the ink functional properties are acceptable without allowing the ink deposit to spread. The ink deposits need to stay in place during drying since, in most cases, the gaps and intentional spacing may be very close.

Drying or sintering the inks is a science in itself. Again, ink products must be designed such that, when the carrier is evaporated, the deposited materials can properly function. Many materials need curing at 160°C for 2 to 3 minutes. This may require a sheeting process with the printed products cycled through an oven. There are very creative curing devices that use near infrared in line dryers (curers) and others that have pulsing light sources that are intense enough to sinter (fuse together) the inks into a basically continuous printed wire. The challenge is to match the potential project with the ink and substrate for the equipment you have or want to add.

Substrate Selection

Substrate selection for a given conductive project is very important. Surface flatness and absorption is very critical in order to print a continuous trace line that will have the consistent electrical property (conductivity or resistivity) per liner inch. Films like PET have been used but calendared and coated papers improve the three-dimensional surface finish so that the ink trace can be printed consistently. Like with all printing, matching the surface energies and surface tensions of the substrates and inks is equally important.

Registration

Registration in most Flexo and Gravure presses are .003 to .004” (75 to 100 microns). Some PE related products can be printed with this registration but designers are stating that there are more products to be printed in an ideal printing press at registration at 5 to 20 microns. There are press manufacturers that are claiming a 20-micron tolerance. With this said, it appears that, for the majority of potential products, a narrow web press around 13” (330 mm) print width will be ideal. With that platform, a hybrid press with Flexo, Gravure and Digital decks would be included in the press. The registration system is one of the major press challenges. Again, as earlier stated, speed in itself can be an advantage as long as the quality is maintained. However, speed can also waste precious materials faster.

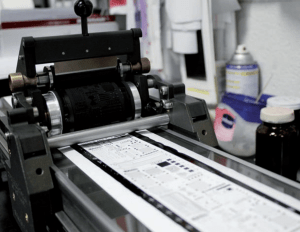

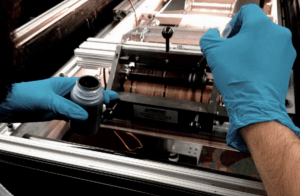

Novacentrix technician applying nano silver ink with a pipette to print flexo at the FlexTech 2015 conference

Surface Engravings

Metering and engravings have been challenging in both flexo and gravure. In gravure, the cylinder manufactures have been able to make 5-micron trace lines. However, trying to meter to keep hazing to a minimum without pulling the ink out of the trace lines has been challenging. It is much harder to meter across machine lines that are parallel to the cylinder axis without pulling the ink out with the doctor blade. Designing the circuit so that lines are diagonal to the cylinder axis is critical. In many cases, curved trace lines do better than straight lines. Gravure printers have found doctor blade materials and tips that do not wipe graphic ink clean will work on conductive inks. As stated earlier, applying only the minimal amount of ink is critical in both flexo and gravure. In some cases involving flexo printing, the reverse metering typically used may tend to shear the ink. So, a forward doctoring chamber or open system would be best.

In gravure, closed cell structures that perform spectacularly in graphic printing do not necessarily allow the deposited ink to be continuous. Etched or laser engraved channels and open cell structures are required over mechanical or electro-mechanical engraving in many applications. We have developed a laser engraved XOS (Extreme Open Structure) structure to overcome many of the challenges. Also, it appears a softer gravure impression rubber roll (60 Shore A) helps with the printing line details.

In the last year, Flexo has come on as the easier choice with the introduction of 8,000 DPI-RIP (raster imaging processor) for plate imaging. An illustrator created vector image, when converted digitally, has been a problem in creating straight edges in the trace lines. With the 8000 DPI-RIP, the imaged plate line is straighter and cleaner, allowing the relief lines to be narrower and placed closer together. However, photopolymer plates may not hold up to specialty inks that are toluene based. There are flexo plate alternatives available in laser engraved EPDM rubber. The other challenge with Flexo from the image carrier is controlling line width growth from impression. What we see in graphics as dot gain can become a problem when printing precise conductive trace lines. This can be helped with keeping the relief between .015 to .021” (380 to 530 microns).

With the availability of anilox rolls in almost any combinations of engraving specifications, flexo has the advantage over gravure in its ability to dial in the ink film thickness for a particular pattern since the pattern is on the plate and the anilox is just the ink carrier. Anilox volumes for printing nano or flake inks do differ, where nano inks are printing nano or flake inks do differ, where nano inks are printed 1 to 3 BCM ( 1.55 to 4.56 cm3 /m2 ), oxide inks in the 3 to 6 BCM ( 4.56 to 9.3 cm3 /m2 ), and flake inks in silver and carbon or graphene 9 to 26 BCM ( 14 to 40 cm3 /m2 ). These are ranges that we have seen but that may not be suited for all inks and substrates. Volume testing is again easier with flexo over gravure. Flexo has the challenge from inks that have low percentage of solids since it has a second ink split over gravure.

Print Environment

The traditional pressroom environment can be an issue. The more detailed the pattern or the more chemically unstable the printed fluid, the cleaner the room and air needs to be. In many cases, the ambient air may need to be a given temperature and humidity in order to not contaminate the printing. Or, air-born dust, if codeposited, may change the functionality of the printed pattern. In depositing advanced materials and, in some cases, liquid electrolytes, corrosion to the equipment would require the printing equipment to be made of different materials than with traditional graphic inks.

The three-dimensional printed trace line is like a wire and the size of the wire is critical toward its physical conductive or resistive properties. As a simplified example, if the printed lines are to carry the current from a 3v battery to a 2.8v LED the voltage drop is calculated in the circuit design. But, if the conductive material is thinner or narrower than calculated, the resistance will increase. The delivered current decreases, the brightness of the LED changes, and the life of the battery is affected.

Conclusion

I covered a wide range to topics to help with your thinking about the challenges associated with starting to contemplate printing functional sensors, devices or circuits. Some of the best advice I can give is to align yourself with a project team that can support the science and physics side of the project so you can just concentrate on the printing side. What I have seen in many incidents is that the advanced materials and electrical engineering project managers do not understand the basics of Flexo or Gravure printing and, in turn, the printers do not understand the basics of electricity. Remember that electrons do not jump very well and variations in ink film thickness and printed line width changes the electrical properties where it can cause the device to not function. Consult the suppliers and universities who have spent the time and money to learn what is needed to make the printed electronics work. As earlier stated, the designs and the required function will be the determining factor in what printing process is best for a given product design.

About the Author: Starting off in paper machinery manufacturing in 1974, 2015 makes 41 years of Industrial experience from manufacturing management and line supervision, plant and facility engineering, manufacturing engineering, production and safety training, technical customer support, application sales, and product development. The last 25 years has put him in pressrooms as a student and a teacher. He has countless hours working as a trouble-shooter and problem solver in pressrooms relating to anilox rolls and gravure cylinders, doctor blades and chambers, pressroom operation, and technical customer support.

To view the original Coating International article click HERE.