Education Is Key to the Transformation

First published in FLEXO Magazine, August 2013 issue.

Written by Gerry O’Hanlon

Growing up in Glasgow, Scotland in the early 1970s and 1980s, companies all around were sponsoring apprenticeship programs for students graduating high school. It was an interesting concept to me that a company would train me for four years and pay me at the same time. An apprenticeship was not easy to get. Generally, you had to either know someone on the inside, or be very lucky to land one. I fell into both categories and landed an apprenticeship with one of the biggest printing companies in Europe. Better still, I earned myself a scholarship to the London College of Printing.

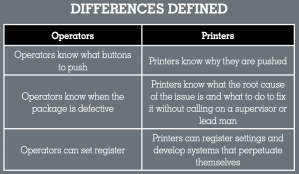

Very early on in my apprenticeship, I learned how to operate several different pieces of printing equipment. Often, I was left in charge of the machine and knew exactly which buttons to push and when to push them. Trusted to run this equipment, I still did not know exactly why I was pushing some of the buttons. It took many years of training and several organized training courses and procedures to get me where I needed to be.

Training offered me the opportunity to get a great education, as well as a chance to land a top job in Scotland—difficult in a country with almost 20 percent unemployment. At its conclusion, I had a trade and was trained by some of the best talent in Europe and in the industry. As a result, I was very fortunate to emigrate to the United States of America in 1998, to train employees at one of America’s top packaging companies. The company that brought me to the U.S. had a desire to create a great training program for its employees and give them a similar opportunity to the one I received.

Today, I take great satisfaction in helping transform some great operators into great printers, using a similar model to the one afforded to me. The industry we work in needs printers, not operators! It needs to listen to the people who perform the tasks necessary to make a quality package. The only way to turn an operator into a printer is to establish a world-class training program at your facility.

PUT PEOPLE FIRST

A wise boss once told me one day when I was complaining about getting calls at all hours of the night with our operators having printing issues. He said “Gerry, it’s all your fault.” Trying to see through the red in my eyes, I asked him “Why?” He told me the following:

1. If you receive a call from the plant and you resolve the problem on the phone, it’s a communication issue

2. If you receive a call from the plant and you come in and fix the problem, it’s a training issue

3. If you receive a call from the plant and you need maintenance assistance, it’s a preventive maintenance program issue

He was so right and his advice changed my approach and my quality of life. I set forth on assembling a logbook of all calls. From there, I set about creating a root cause analysis for each call and then implementing corrective/preventive actions for each issue. Within one year, I was receiving no calls from the plant.

What we did to rectify the situation was not perfect, but we did improve our communication, our training, and our preventive/predictive maintenance. Most importantly, we involved our most valuable asset, our people.

The employees operating our equipment every day earned the title and opportunity to do so, however, we often fail to trust them to assist in developing training programs and continuing to build on their own education in our industry.

How would you feel if you found out some of the original equipment manufacturers that we purchase millions of dollars of equipment every day from failed to invest in their employees’ education and did not grant them opportunities to train on the equipment they use and build every day?

RESOURCES & RESULTS

There are state and federal initiatives providing grant money to bring in experts who can train your staff on the trade.

One great resource available to everyone in the flexo industry is Flexographic Technical Association’s Flexographic Image Reproduction Specifications and Tolerances (FIRST). The intention of this manual is to provide all participants in the flexographic reproduction process with a common set of guidelines, tutorials and data that can be used as communication and production tools. Some of the world’s leading companies and tradesmen contributed to the development of this manual. If used, it can only help improve any printer’s process and education.

Many of your company’s vendors also offer training programs and as mentioned before, many are free. A statistic that blew my mind when joining Harper Corporation was that, 80 percent of our business comes from damaged or worn rollers, yet our company has a full technical support team of highly skilled individuals that spend hundreds of thousands of dollars each year educating and supporting our customers on care and maintenance of their anilox rolls and sleeves.

Harper also offers a free WalkingSeminar at its manufacturing facilities in Charlotte, NC, and Green Bay, WI. They allow customers an inside-look at all aspects of anilox manufacturing. Participants have the opportunity to interact with the Graphics Center and Graphic Solutions teams and learn how to increase press speeds, reduce downtime, print consistently, cut waste, trim set-up time and control inventory.

If everyone reading this article actively improves his/her training and press maintenance programs, our industry will thrive competitively for many years to come. Everyone should agree that the most valuable asset in our industry is our people. If we do not invest in the education and training of our people, our industry will throw away countless dollars and continue to struggle unnecessarily to compete.

If you continue to improve and your competition does not, you will win. Status quo is not a survival or evolutionary tactic. The printing industry needs printers, not just operators, to survive! Invest in your operators and give them the opportunity to become great printers.

About The Author: Gerry O’Hanlon has 25+ years of experience in the printing industry and holds a City & Guilds from the London College of Printing, which equates to a Bachelor’s Degree in Printing Management and Printing Science, accredited by Clemson University. Born in Glasgow, Scotland, O’Hanlon immigrated to the United States in 1998. O’Hanlon’s expertise has been shaped by his professional history, which includes a four-year apprenticeship with John Horn-Rexam. He has designed numerous team building activities, facilitated multiple training classes, and led cost-saving Six Sigma initiatives.

About The Author: Gerry O’Hanlon has 25+ years of experience in the printing industry and holds a City & Guilds from the London College of Printing, which equates to a Bachelor’s Degree in Printing Management and Printing Science, accredited by Clemson University. Born in Glasgow, Scotland, O’Hanlon immigrated to the United States in 1998. O’Hanlon’s expertise has been shaped by his professional history, which includes a four-year apprenticeship with John Horn-Rexam. He has designed numerous team building activities, facilitated multiple training classes, and led cost-saving Six Sigma initiatives.

To view the original Package Impressions Magazine article click HERE.