Harper Is Scientific – Anilox Technology Development

The anilox roll is widely known as the heart of the flexographic press and Harper is very proud to announce our continuing development of new anilox manufacturing technology. To someone on the outside looking in over the past few years, the anilox roll may have seemed a dormant part of the Flexographic industry. However, Harper has been very busy behind the scenes developing further advancements to take the manufacturing of anilox rolls to a whole new echelon.

The technology of manufacturing an anilox today as compared to 5 or 10 years ago is not the same. Our customers today are under more demand for consistency, repeatability and tighter tolerances. Everything is measured in the printing world from ink viscosity, dot gain, density, feeds, speeds, waste, etc. With that in mind, Harper has taken the same systematic approach in the manufacturing of anilox rolls.

Harper has made major investments and committed a massive amount of time and focus in order to scientifically measure every process of manufacturing an anilox roll. A major part of Harper’s investments have come in the form of new technology, equipment, software development and instrument purchases to scientifically measure our processes in a constant effort to maintain consistency.

In our ceramic coatings process (Echoplasma) we have purchased a large number of state of the art thermal spray plasma systems. Some of these purchases are replacements as part of our continuous improvement program and others are due to increased customer demands. We will be cycling in more touch screen thermal spray units within the next year.

Additionally, as part of our ISO certification protocols we spray sample coupons from every spray booth monthly and each coupon is evaluated for hardness, density and porosity by a certified outside independent laboratory. The tracked results help us to maintain consistencies in the coatings departments at all locations. Coating consistency, besides being critical criteria, is also a top priority at Harper. The coating of the anilox is the foundation that ensures all subsequent processes stay consistent.

The hardness of our ceramic coating averages 1200 Vickers and is operated in a range between 1100 to 1300. Some may ask why this is important and from experience, we have learned ceramic hardness above 1300 Vickers changes the mechanical property and the ceramic becomes too hard and consequently, brittle. This could cause the coating to crack under pressures normally associated during regular press operation. By keeping the hardness of the ceramic coating within this range, we are able to provide the customer with the hardest ceramic possible to ensure longevity, while at the same time allowing it to remain very durable.

Maintaining a minimal amount of porosity is just as important as maintaining the correct hardness. Our porosity averages ½% with an upper limit of 1%. Keeping porosity to such a low level allows us to maintain consistency when we engrave the line screen as well as keep a uniform volume across the roll face. We also have one of the first employees in the Flexographic industry to be a certified CTSO thermal spray specialist to help maintain these standards. For example, when engraving a 1200 line anilox with 2.0 BCM if you have porosity (coating voids) that measures 25-30 microns across it becomes impossible to hold a consistent cell shape or volume because the opening of a 1200 lpi cell is only 19 microns. It will be impossible to create the cell wall structure necessary to prevent the low percentage dot from being overloaded with too much ink. If the opening of the cell on the anilox is greater than the plate dot you will have dirty print with inconsistent, low quality results.

Due to increased customer demand, we have added a new CNC cylindrical grinder to the grinding and superfinishing department. As press speeds and line counts increase so has the importance of the surface finishes of our rolls prior to laser engraving. As part of our superfinishing SOP every anilox surface is measured using a non-contact surface finish instrument and the Roughness Average (RA) is recorded. RA measuring gauges are used to measure roughness after polishing and before laser. This is very important because roughness plays a critical role in determining how a real object will interact with its environment. All other things being equal, rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces. Roughness is often a good predictor of a mechanical component’s performance and longevity since irregularities in its surface may form cracks or corrosion. The lower the RA numbers, the lower the amount of roughness of a component. Every anilox roll we manufacture, regardless of specification, must have a 3.0 or better RA finish before being laser engraved. This low RA finish cannot be obtained if it was not for the less than 1% porosity of our ceramic. To put this in perspective, we were told ceramic imaged cylinders were not possible because ceramic by nature has too much porosity. For the past 5 years Harper’s XDI family of laser imaged ceramic gravure cylinders print without hazing because of our proprietary ceramic and finishing practices.

One way in which Harper controls consistency in the laser engraving machines is to give our operators the best possible surface to engrave. This allows our engraving machines to provide more consistent quality as well as maintain smooth cell tops. In a printer’s world this could mean a lower roughness of the anilox surface, longer blade life, and reduced scoring.

Harper globally has also extended its XLT™ technology with 9 new state of the art versatile ALE Hercules laser engraving systems, 5 of which are 500 watt models. We also have plans to add another 4 lasers in the next 18 months. Our 500 watt fiber optic engraver contains the latest laser technology available. As C02 laser technology became obsolete in our anilox world, the new fiber optic technology became our standard. Low line screen engravings with extended or extreme volumes were at minimal a challenge when using CO2 technology.

However, with the 500 watt fiber optic technology we are not only able to achieve standard low line screens, but have been able to expand our engraving charts beyond what was previously possible. Harper is able to now achieve a broader range of engravings with our XLT™, XVR™, LaserKote™, Gravure Polish and XDI™ product lines. We offer more extensive engraving ranges than any other anilox manufacturer.

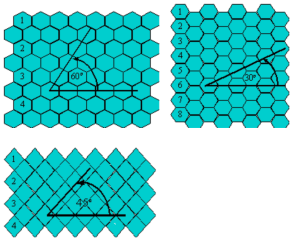

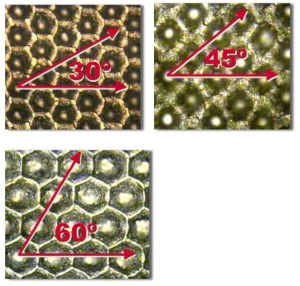

Harper’s laser technology goes much deeper than just the wattage of the lasers. The cell profiles are much more defined, and tops of cell walls are much more crisp and smooth. Our quality, consistency and repeatability continues to be unmatched by any other anilox manufacturer. Since Harper has pioneered and still strongly supports the 60 degree hex, we believe it is the premier engraving geometry being offered to the industry.

With that in mind, we continue to stay focused on improving upon this proven technology. Many competitors have been pursuing the quality and consistency that Harper provides with the 60 degree. But they have struggled to match it, especially in the higher line screen range. Because of such challenges our competitors have introduced different engraving patterns in an attempt to compete. However, our Harper GraphicSolutions team has run countless printing trials using every pattern and geometry available. Results of these trials along with the manufacturing innovations, the Harper 60 degree cell continues to be the most proven consistent anilox available in the market.

It is not possible to make consistent engravings if you are unable to consistently measure the line screen and volumes. Harper was the first anilox company to embrace and use Interferometry, which the FTA FQC committee has listed as the most repeatable method to measure anilox volume at the 2011 Forum. Harper exclusively uses 3DQC’s from MicroDynamics. Every anilox we engrave is set up in the laser using 3DQC measurement verification prior to engraving and then checked across the anilox surface after engraving. Harper has also developed and incorporated an internal proprietary software package to work with the 3DQC.

This gives us a quantifiable measurement of cell wall contact in the form of a percentage.This proprietary tool allows us to maintain a consistently smooth surface after engraving which will help rolls perform with less wear, scoring, and provide extended performance.

This innovation is valuable because presses are running at continually increasing speeds. Harper is proud to be the first to have this measurement capability.

Lastly, we also recognize that behind every new technological advancement or piece of equipment, stands highly skilled and dedicated employees. It is for this reason that we constantly strive to ensure that our employees are continuously improving. Opportunities are provided for additional training on a regular basis. In fact, we give our employees the opportunity to visit a local technical college where they learn the basics of Flexographic press operation and are able to physically operate a variety of presses.

This offers valuable experience, relevance, and insight, which the employees can bring with them to apply the knowledge gained as they manufacture the world’s finest anilox rolls.

For over 40 years, Harper Corporation of America’s commitment to service and technology continues to be our global focus as the leader in anilox manufacturing, both new and remanufactured. This commitment provides our customers with the most consistent quality anilox and service – order to order; year after year.

The founders, Ron and Katherine Harper retired and sold Harper Corporation in 2006 to their highly experienced top level management team. The new ownership team consists of the Harper’s son Jim Harper and grandson Ronald “Lee” Harper. We stay committed to continue the legacy of the Harper’s position, dedication and vision toward the Flexographic industry.

This commitment provides our customers with the most consistent quality anilox and service – order to order; year after year. In addition, Harper continues to be an excellent resource bringing the Flexographic industry together in forms of WalkingSeminars, Roadshows, on-site HarperGraphics Solution’s, trade shows and technical articles. This allows everyone to give and gain as much knowledge through education that the Flexographic industry has to offer.