First published in Flexible Packaging Technology, Quarter 1 2015 issue.

Written by Harper Technical Solutions Advisor, Sean Teufler.

Many printers understand that line screen and volume are the two most important specifications that affect the performance of the anilox. Often it is not well explained what the terms mean and how the importance always affects them.

Let’s begin with the line screen. Line screen is commonly associated with cell count. The terms are interchangeable and are often mentioned as linesper-inch and cells-per inch, known in units as LPI and CPI respectively. The function of the line screen is to support the smallest structure on the plate. These structures could be the smallest dot such as a highlight dot, or perhaps fine print you would find in a security feature. In terms of an engraving’s lifespan, line screen does not change until either the ceramic itself is removed during the initial remanufacturing process.

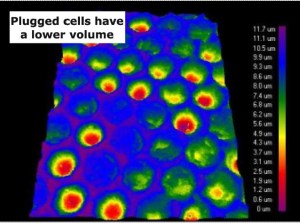

Volume is the function that determines ink film thickness and color strength in terms of a consistent ink. In terms of lifespan, volume is different in nature entirely from line screen. The actual volume of an engraving is entirely dependent on the amount of wear on the cells and the state of cleanliness. This leaves the door open for inconsistency without monitoring and measurement. Cells plugged with ink reduce volume. Wear is permanent until remanufacturing is done, while cell plugging is a temporary condition that can be remedied by cleaning the cells. When it comes time to select line screen and volume, keep in mind the anilox is there to support two functions: the image on the plate and the requirements for color strength. In that fashion, the anilox is the intermediary in the communication between the ink and plate image. While volume is determined by ink strength, other factors such as ink resolubility and ink flow must be kept in mind as an ink that does not want to print optimally will make for inconsistent print and quality issues. We will now explore the refinements as it relates to line screen, volume, fixed color palette and in the care of the anilox engravings.

Volume is the function that determines ink film thickness and color strength in terms of a consistent ink. In terms of lifespan, volume is different in nature entirely from line screen. The actual volume of an engraving is entirely dependent on the amount of wear on the cells and the state of cleanliness. This leaves the door open for inconsistency without monitoring and measurement. Cells plugged with ink reduce volume. Wear is permanent until remanufacturing is done, while cell plugging is a temporary condition that can be remedied by cleaning the cells. When it comes time to select line screen and volume, keep in mind the anilox is there to support two functions: the image on the plate and the requirements for color strength. In that fashion, the anilox is the intermediary in the communication between the ink and plate image. While volume is determined by ink strength, other factors such as ink resolubility and ink flow must be kept in mind as an ink that does not want to print optimally will make for inconsistent print and quality issues. We will now explore the refinements as it relates to line screen, volume, fixed color palette and in the care of the anilox engravings.

Refinement of line screen and volume

A number of factors have led to the drive for refinement of line screen and volume. The first would be the desire to take flexographic quality to an ever higher level in order to meet or exceed offset and gravure printing. In order to engage in the finer plate screens, a couple of important changes had to happen.

The first is in the laser technology itself. Original lasers consisted of CO2 technology and this limited the beam width to only allow for up to 1200 lpi. The adoption of fiber optics allowed the line screen possibilities to increase dramatically to upwards of 2000 lpi in use and 3500 lpi in testing. This all had to do with the narrower beam width that fiber optics provides.

The second factor is the changes in ink dispersions. The ability to more finely grind ink pigments allowed for greater color strength, which then in turn allowed for the possibility of thinner ink films that would still flow and print cleanly. Plate technology has played a part as well because of the switch from analog to digital and the increased potential for refinement of the plate screen. The advancements of all three technologies, (anilox, ink and plate) have worked together at various points to continue the greater push for refinement of line screen and volume. The past ten years have seen rapid changes specifically in the development of enhanced plate technology. These plate characteristics entail reversed dot structures in both solid and screen print surfaces.

Texturing, graphic images and microscopic pores distributed throughout the flat surface all act to carry more ink. If the converter is looking for increased ink density or color strength, this can be done with this technology alone without having to increase anilox volume.

The two main advantages of including this technology are reduction in the potential in halo from ink pushed to the edge of the plate images and an opportunity to adjust volume downward to maintain color strength. Remember to be aware of what technological advances in plate and inks you are going to employ before determining line screen and volume.

Refinements related to fixed color palette

These same refinements have led to the ability for seven color process printing, known as fixed color palette, CMYKRGB and CMYKOGV. This is essentially traditional Cyan, Magenta, Yellow and Black process colors in combination with three bump colors of Red/Green/Blue or Orange/Green/Violet to expand the achievable color gamut. Expanded gamut printing presents some challenges to anilox producer as a number of factors come in to play in order to be successful. While volume is important to every anilox, it becomes more critical to an anilox used for expanded gamut. This means adherence to volume tolerances and measurement as well as the utilization of a stable ink where color strength at a printable viscosity is achievable. There are two ways to determine linescreen and volume requirements for expanded gamut. First is to utilize a calibrated ink set that has already determined line and volume requirements for CMYK and the RGB or OGV. The seven are often not the same but two groupings of line/volume. If these variables are unknown, the second way is to test through a banded anilox has various linescreens and volumes to test the parameters set forth by the ink supplier to determine what ultimately will be needed. For example, CMYK may see a range of 800-1200 linescreen and a volume range of 1.5-3.5 BCM for the 800 to 1.5-2.5 BCM for the 1200. Volume tolerances should be within a +/-0.1 BCM. For RGB/OGV donor colors, you may be looking at stronger volumes and slightly lower linescreens relative to the CMYK set. Solvent inks are a special case for expanded gamut as the inks must be tuned for the press speeds so the ink dry rates yield wet ink transfers to the substrate, not before or after the substrate. Testing at the proper run speed for established solvent ink sets or test solvent ink sets is critical to the success of determining linescreen and volume. UV and waterbased inks are typically not speed-sensitive unless there are ink station starvation issues that wou Id affect transfer and falsify the result.

Cleaning, measurement/ inspection and storage

There are other factors related to the printed product that aren’t linked directly to color or graphic requirements but are important in their own right to sustain the anilox inventory and validation of your choices in line screen and volume. These factors are cleaning, measurement or inspection and storage. Cleaning begins and ends with cleaning ability and effectiveness. This comes down to the solution you use for cleaning and the technique that employs it. For cleaners, use a cleaner that works to emulsify the dried inks in the cells. Use the cleaners as directed. If it says to leave it on there for a few minutes, then do so. The more dried the ink, the longer it takes for any cleaner to emulsify it. Make sure the cleaner you are using is safe for the anilox. This means cleaners that are friendly to aluminum and mild steel subsurfaces. If a caustic cleaner is used or preferred, be sure to rinse very well. The rinse step is important to any cleaning, but it is critical to preventing blistering of the underlying metals if caustic (very high or low pH) cleaners are used. Be sure to use the proper PPE (goggles, gloves, etc.) as specified on the Material Data Safety Sheet and Technical Data Sheet for the cleaner.

There are other factors related to the printed product that aren’t linked directly to color or graphic requirements but are important in their own right to sustain the anilox inventory and validation of your choices in line screen and volume. These factors are cleaning, measurement or inspection and storage. Cleaning begins and ends with cleaning ability and effectiveness. This comes down to the solution you use for cleaning and the technique that employs it. For cleaners, use a cleaner that works to emulsify the dried inks in the cells. Use the cleaners as directed. If it says to leave it on there for a few minutes, then do so. The more dried the ink, the longer it takes for any cleaner to emulsify it. Make sure the cleaner you are using is safe for the anilox. This means cleaners that are friendly to aluminum and mild steel subsurfaces. If a caustic cleaner is used or preferred, be sure to rinse very well. The rinse step is important to any cleaning, but it is critical to preventing blistering of the underlying metals if caustic (very high or low pH) cleaners are used. Be sure to use the proper PPE (goggles, gloves, etc.) as specified on the Material Data Safety Sheet and Technical Data Sheet for the cleaner.

How do we know it is cleaned?

This is where inspection comes in. In most cases cell condition can easily be determined with a simple 200x -400x power scope. Higher line screens need the 400x power optics for good observation. A center-lit scope is the best so the illumination does not distort the image to your eye. Most printers can tell if the cells are showing wear and if the cells are coming clean. If a measurement is required, there are a number of scope systems that will do volume measurement, be it calculated or calculated for you. There are many intricacies to volume measurement involving the optics used, the number of cells in view, the amount of illumination and how the fringe areas of the cell are included. Measurements are most effective when you have a correlation roll with various engravings from your anilox supplier to help you both learn how to use the scope and stay within the same measurement parameters.

Lastly, you have storage. There is nothing more frustrating to a converter than to have an anilox damaged when all these other procedures are in place and the converter is short a much-needed anilox in their inventory. Storage isn’t just a place to put the anilox. Storage must protect the anilox as well and not become part of the problem. Ideal storage is located near where the aniloxes are used in press and near where they will ultimately be cleaned. Mobile storage should always be considered to help the anilox get from press to a cleaning area that is a distance away. If storing sleeves, the sleeves should be well supported by the pin they are slid upon if stored horizontally. This support means filling the inside of the sleeve so the sleeve’s weight is distributed as evenly as possible. Any surface the sleeve ends touch should be padded and remain padded to avoid contact with metal of any kind, especially bolts and welds. Traditional aniloxes with journals also need care. Any supports for the journals should be padded and no metal should be exposed so if contact is made, the engraved surface does not suffer as a result. The best suggestion I can make is to have your cleaning, measurement, inspection and storage examined by your anilox supplier’s technical support. They are used to seeing these issues and hazards and should have the capability to help you. Regardless of how you define your linescreen and volume, the key to successful flexographic printing is how you determine and deploy your selections in the most efficient manner possible.

Taking into account the print demands, ink and plate technologies and the type of flexo printing you are targeting, you can dial in the process to get repeatable results every time. Keep in mind that once the correct line and volume has been selected the enduring lesson is to keep the engravings clean, replace them when worn and to store them safely to get the full service life.