Examining Options & How to Make The Right Choice

First published in FLEXO Magazine, June 2015 issue.

Written by Harper GraphicSolution Director, Alexander James

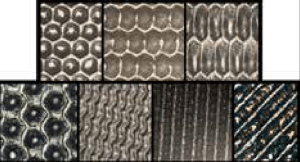

Anilox engravings have evolved from a rudimentary ink carrier—originally a 45 degree quad engraving, primarily for solid ink coverage—to a highly sophisticated carrier for a wide variety of applications from varnishes and laminates to specialty inks.

With all the various needs and different application requirements in our industry, thankfully today there is also a wide range of anilox engraving and specifications to choose from. They include:

• XLT 60 degree

• 70 degree hex

• 45 degree quad

• 30 degree channel

• Weave

• KatRon (elongated cell)

• 45 degree trihelical

• 60 degree XTR

• 70 degree XTR

• 89 degree XTR

COATINGS

Laminates, varnishes and adhesives: Each has a different purpose and when determining what anilox specification is needed, it will first be necessary to request the Technical Data Sheet (TDS) from your coating supplier. The TDS will provide useful product specific information, such as the application method, appropriate substrate, recommended coat weight, viscosity or pH, percentage solids, dry rate, storage and handling.

For the anilox supplier, the useful information on the TDS includes the target coat weight, percentage solids and the weights per gallon. Coat weight can be based on lbs./ream, gram/square meter or target thickness in microns. Knowing the application method will also be necessary; is it a gravure coating station or traditional flexo application? Will the application be in a two roll or chambered system? Providing this information will enable your anilox supplier to make the right recommendations.

As an example, if the coating is very thick and is going to be applied to an uncoated substrate, then it makes sense to use large cell engravings, such as the 45 degree quad, 70 degree hex, KatRon or one of the channel engravings. Uncoated substrates will necessitate heavier coatings because of the absorbent characteristics of the material. Weave engravings, 30 degree channel, 45 degree trihelical, 60 degree XTR, 70 degree XTR or 89 degree XTR; channel engravings naturally will lay down lots of product due to the continuous open channel patterns. Some very thick coatings will need the channel engravings in order to achieve the recommended coat weight. Coatings require thicker application and, naturally, the larger open engravings are a good fit. With the information provided on the TDS and a Coating Application Worksheet, your anilox supplier will be able to recommend the correct anilox specification for your needs.

As an example, if the coating is very thick and is going to be applied to an uncoated substrate, then it makes sense to use large cell engravings, such as the 45 degree quad, 70 degree hex, KatRon or one of the channel engravings. Uncoated substrates will necessitate heavier coatings because of the absorbent characteristics of the material. Weave engravings, 30 degree channel, 45 degree trihelical, 60 degree XTR, 70 degree XTR or 89 degree XTR; channel engravings naturally will lay down lots of product due to the continuous open channel patterns. Some very thick coatings will need the channel engravings in order to achieve the recommended coat weight. Coatings require thicker application and, naturally, the larger open engravings are a good fit. With the information provided on the TDS and a Coating Application Worksheet, your anilox supplier will be able to recommend the correct anilox specification for your needs.

SPECIALTY INKS

Specialty inks, such as fluorescent, thermochromatic, metallic and pearlescent, will require different anilox specifications. Some may need volumes ranging from 4.0 bcm to 8.0 bcm and others may need more. For this category of inks, formulation and pigment grind size will be factors that must be considered. Again, the TDS will be most helpful.

Communication between the customer, ink supplier and anilox supplier will be the most important factor. For each specialty ink, it is critical to discuss the expectations, goal and production setup. You can have the desire to print a brilliant, rich fluorescent color, or apply sparkling pearlescent ink; but do you have the right setup to dry the inks at production speeds?

From the anilox recommendation side, the critical criteria will be the particle size. A good rule of thumb is to keep the cell opening a minimum of twice the size of the largest particle size. For example, if you are applying pearlescent inks with 15-µ. to 20-µ. size particles, your anilox should have, at the minimum, an opening of 40-µ.

From the anilox recommendation side, the critical criteria will be the particle size. A good rule of thumb is to keep the cell opening a minimum of twice the size of the largest particle size. For example, if you are applying pearlescent inks with 15-µ. to 20-µ. size particles, your anilox should have, at the minimum, an opening of 40-µ.

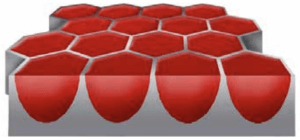

Once the minimum opening has been determined, you need to look at the anilox volume. When thinking of volume for specialty inks with large pigments, don’t get distracted with volumes that may have very deep engravings. After all, the pigments will need to be easily released from the anilox in order to achieve the desired effect. Anilox engravings that are very deep will invariably have a conical shape that can easily trap some of the large specialty pigments. There will need to be a balance between the anilox opening and the volume (depth). Try to keep the cell depth to opening at a ratio in the range of 23 percent to 33 percent.

To calculate the depth to opening ratio, use the following formula: D/O Ratio = Cell Depth/Cell Opening x 100.

You will need to consult your anilox supplier for the depth and opening information, which is to be provided in microns. Logically, if you have deep engravings when applying large pigment, the anilox roll will have a tendency to plug easily. Sometimes, as in the case of pearlescent inks, keeping the ink in suspension for proper application will be part of the challenge.

WHITE INK

White ink for most printers is the highest percentage of ink consumed. Part of today’s trend is to have high opaque whites, using UV, water and solvent based inks. When making recommendations for white ink, it is always best to have a specific opacity target. Your opacity target will have an impact on the anilox specification.

When needing volumes in the 8.0 bcm to 12.0 bcm range, the logical choices are the 60 degree hex and the 30 degree channel engravings. If you are applying white to an uncoated substrate, then you should consider larger cell engravings such as the 70 degree hex and the KatRon (elongated cells) engravings. As you move on to the high opaque whites, you’ll need more volume; in that situation the various channel engravings are great options: Weave, 45 degree trihelical, 60 degree XTR, 70 degree XTR or 89 degree XTR.

In today’s market, combining the latest solid plate pattern options with your anilox engraving choices can have an impact on your opacity. The solid plate pattern can result in better laydown—mottle free—and also lower the anilox volume needed in order to achieve your desired opacity target. This is exciting, because that can result in significant white ink savings.

SOLID & COMBINATION PRINTING

With solid and combination printing, the XLT 60 degree hex is a great choice to start with. However, when printing on uncoated surfaces, it is an opportune time to take advantage of the variety of engraving options. Rest assured that, depending on your ink system and substrate, there is an engraving that will meet your needs. In every situation, it is key to have a defined print target with tolerances. This will enable your anilox supplier to be able to consistently provide the anilox specification that meets your needs.

Combination printing, solids and vignettes require a balance between hitting your target solid color and also printing a clean vignette. In that situation, there will be a need for your anilox to have enough volume to achieve the solid, and also a high cell per inch specification, so you can also print a clean vignette. XVR 60 degree anilox engravings with higher cell per inch specification and deeper volumes are the best fit. These engravings, along with proper ink formulation, work well for combination printing. If your minimum dot is large—4 percent or higher—then you can consider other options like the 70 degree hex and other channel engravings. This is especially applicable for the paperboard and corrugated market segments.

PROCESS PRINTING

Process printing requires defined print targets (with tolerances). Having specific print target information will always make it easier on your anilox supplier. Along with your print targets (and tolerances), your anilox suppliers will also need to know the type of ink, substrate, plate dot lpi and target minimum dot percentage. With this information, your anilox supplier will be able to make a sound recommendation.

Consistency and repeatability are part of the print requirement for process printing and for anilox suppliers, the option that delivers those needs, as well as best engraving, is the XLT 60 degree hex. The structured qualities of this type of engraving will assure that you will be able to hit your print targets with the most consistent product. It is critical to know what your minimum dot lpi will be and it is important to measure its diameter. Once you know the specification of minimum dot diameter (in microns) you should keep the anilox cell opening equal to or less than that diameter.

Keeping the anilox cell opening equal to or less than the minimum dot diameter will ensure you can achieve the desired quality of clean printing, especially on highlights and vignettes. With those criteria, your anilox will deliver the right amount of ink to your plate and not over ink your minimum dots, avoiding what is sometimes referred as “dirty printing.”

By far the most popular anilox engraving use in our industry is the XLT 60 degree hex. This is due in large part to the fact that the 60 degree hex has the most support structure compared to the other engravings. Regardless of what your print needs are, rest assured there is an anilox engraving that will work for you. Sometimes this may require banded roll testing in order to determine which engraving and specification will work for your situation. This is especially true when testing a new application and product, or a change in your print process.

In most cases, the key things that your anilox supplier will need to know in order to make the correct anilox recommendations are the following:

• Print target (with tolerances)

• Plate lpi

• Minimum dot diameter (in microns)

• Type of ink

• Press type

• Production speed

• Type of substrate

When you need an anilox recommendation for coatings, specialty inks or white inks, it will be important to clearly communicate the TDS information of the products you plan on using, as well as the goal or print target and your measuring method. Measuring methods, unfortunately, are often assumed, and not knowing exactly what method is used can lead everyone involved astray. Anilox specifications of cpi and bcm have numerical values and tolerances that can correlate to your print target and tolerances. Work with your anilox supplier to determine the right engraving choice and specifications that will meet your needs.

About the Author: Alexander James is the director of Harper GraphicSolutions, the technical division of Harper Corporation of America, and has a Masters of Science degree in graphic communications from Clemson University, as well as a Bachelor of Fine Arts degree from the University of North Carolina at Asheville, NC. With more than 20 years experience in the graphic arts industry, Alex has participated in many industry related events as guest speaker/presenter. He is also FIRST Level III Implementation Specialists Certified and has authored numerous technical flexographic related articles.

About the Author: Alexander James is the director of Harper GraphicSolutions, the technical division of Harper Corporation of America, and has a Masters of Science degree in graphic communications from Clemson University, as well as a Bachelor of Fine Arts degree from the University of North Carolina at Asheville, NC. With more than 20 years experience in the graphic arts industry, Alex has participated in many industry related events as guest speaker/presenter. He is also FIRST Level III Implementation Specialists Certified and has authored numerous technical flexographic related articles.

To view the original FLEXO Magazince article click HERE.