Key factors in selection and maintenance of anilox rollers to improve quality in highend flexo printing

First published in Flexo & Gravure Global Magazine, December 2013 issue.

Written by Gregory Harms

There is a huge demand on flexographic print shops to reproduce high quality photographic images on packaging substrates. Previously, this area was dominated by the gravure and offset processes, but due to technological progress in flexo printing this has certainly changed. Against this background, understanding the relationship of printing dots to anilox cells will help change the flexo printing process from an art to a science. In this article, some of the steps and aspects needed to take into consideration when selecting the correct anilox for high-resolution halftone printing are discussed. In this context, plate material and screen ruling (lpi) are decisive factors in choosing the most suitable type of anilox.

Influencing Factors

Substrate

In flexographic printing, a wide range of substrates ranging from papers (uncoated, coated, kraft paper etc), foils, and films can be used. As all substrates will behave differently in print and have a different absorption rate, ink film thickness will be crucial.

The choice of substrate and customer requirements will determine the selection of the respective ink system. In general, there are three well-established systems: waterbased, solvent-based, and UV curing inks. The advancement of ink dispersions contributes to improved ink density and reduced dot gain

Doctor blade

Doctor blades and chambered doctor blade systems have also improved over the years and play a key role in controlling the thickness of the ink layer. Blades are available in different thicknesses, tip designs, and materials like metal, plastic, and plastic composite. Tips come in different designs like lamella, radius or bevelled and thickness is a key factor. Values of 0.006”–0.010” (0.15–0.25 mm) would work well in high-quality flexo printing.

As a rule of thumb: »The smaller the tip the cleaner the wipe«

As the ink layer should be as thin as possible, absorption is going to be key factor. Depending on the respective substrate, the absorption rate is found to be related to fluid substrate contact angle and fluid properties. For coated paper, the absorption rate depends on the base paper absorption rate, the coating pore size, coating binder level and fluid-coating contact angle. Films and foils do not have any absorption problem but have to be coated or pre-treated to achieve ink adhesion.

Ink systems

Water-based ink systems have transformed from pH sensitive and maintenance dependent formulations to color matching capabilities with little to no maintenance required. UV inks have maintained color strength while viscosities have decreased to near water-based ink level. Flexography is very much about solid ink density and color strength, both depending on the pigments formulated by the ink manufacturers. Solvent-based inks consist of three main components: carrier fluid, pigment, and resin. Technically, solvent-based inks refer only to the oil-based carrier.

Printing plates

There are a large number of plate types available to choose from to give the one that best fits your process. To determine which is needed to achieve e.g. 150 lpi (59 l/cm) or 200 lpi (79 l/cm), testing a couple with a one color finger print trial, or four color finger print trial might help. The minimum printed dot size is determined not only by the printing process but also by the platemaking process.

A line screen is the measure of how many halftone dots are printed in a linear inch (lpi). Currently, 150 lpi (59 l/cm) halftone screens are commonplace, whereas highend flexo print shops in certain markets like beverages, body care, and pharmaceuticals are printing with 200 lpi (79 l/cm) halftones or even above.

Mounting tape

In addition, plate mounting tape is specially designed for providing high-quality halftone printing and superior versatility for flexo. They are available in the medium to soft range according to the requirements of printing plates and subjects.

Key factors

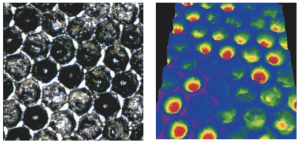

The key factor in delivering the desired ink film thickness is the anilox roller. To control this tool, the units lpi (l/cm) and bcm (billion cubic microns) resp. cm3 /m2 are used. Lines per inch (cm) means the number of lines (cells) in one linear inch (cm) measured in the angle of the geometry. Volume is measured in billion cubic microns measured in a square inch (cubic cm per sqm). Another key factor is the cell opening, which should not be much larger than the minimum printed dot size on the plate.

This is due to the fact, that if the opening on the anilox is too big, the dot may over-ink, causing dirty print and dot bridging. On the other hand, if the opening is too small, the dot is only contacting cell walls and therefore not getting enough ink to transfer the desired ink layer thickness.

When printing with halftone screens of 150 lpi (59 l/cm) and above, the minimum printed dot size will be 1–2%. In this case, 1% is roughly a 19 micron and 2% is roughly a 27 micron dot size. This means, that anilox rollers with 900 lpi (and above) have a working opening of 25 micron falling between the two percentages. Going even higher, the 1200 lpi anilox has a 19 micron opening which may solve some printing problems.

Test runs

However, before choosing the lpi and volumes, running some print tests using a banded roll is the best way to make the right choice of anilox rollers. Complete a thorough series of trials with the above elements to ensure noticeable differences are observed.

In flexo printing there are a lot of factors which can change the results of the process. This includes the ink systems, whether it’s water-based, solvent-based or UV curing. For example, for the banded roll, testing at 900 lpi and 1200 lpi is recommended, because typically it is good to test the lowest line screen and then the highest with a range of volumes in between to help to achieve the desired print results. For determining the right volumes the density specifications from the FTA – 1.1 Yellow, 1.25 Magenta, 1.35 Cyan and 1.55 or higher on the Black should be used. Usually Yellow and Black are typically the weakest colours, higher volumes are needed in contrast to the stronger Magenta and Cyan hues. For water-based inks, a good range and starting point would be 1.4–2.0 bcm (2.17–3.1 cm3 /m2 ), solvent-based 1.6–2.5 bcm (2.48–3.875 cm3 /m2 ), and UV 1.0–2.0 bcm (1.55–3.1 cm3 / m2 ). The numbers of bands are determined according to the size of the press. For example, five bands like 1200 lpi/1.0 bcm; 1200 lpi/1.2 bcm; 1200 lpi/1.4 bcm; 900 lpi/1.6 bcm; and 900 lpi/2.0 bcm will give a good range of density.

Cleaning the anilox

Cleaning the anilox is a crucial part of the process. This helps to maintain the ink volume and cuts press downtime through reducing the efforts for colour matching.

Ink volume can be affected by plugging and wear. Of the two there is only control over plugging. In this respect, having a good cleaning procedure and documentation on press is a very helpful tool. Whether water-based, solvent-based or UV curing inks are used, there is always the need to have a good cleaner. It not only should be able to break down the ink, but will also stay wet while cleaning. It is not recommended to use something that will flash fast and dry like water or solvents. After cleaning the roll on press the roller has to be wiped down with a solution that is equal parts water and alcohol. This will get the cleaner out of the cells and off the face of the roll to ensure good ink release next time.

In addition to manual cleaning, a good off-line cleaning machine is also helpful and there are several good products to choose from. Recommendation: Always run to the manufacture specifications, also understand how the machine works, and know the products in use.

However, the biggest step in keeping the aniloxes in good shape is to inspect them before and after cleaning using a scope or a camera system. It is a great practice to know what the roll looks like before and after cleaning. In this context it should be documented when and who did the cleaning of the roll so its progress can be tracked. Moreover, this documentation can help to determine a lot about the roll and how well it is being taken care of. If a camera system for roll measurement is available on-site, the anilox supplier should perform a roll audit at least once a year to determine the volume of the rolls. This is crucial in terms of maintaining the densities on press and decreasing downtime.

The awareness relating to the condition of the rolls should range from wear to cell wall damage. Taking this seriously will contribute to increasing machinery uptime, keeping the rejection rate low, and improving product quality.

Summary

Picking the correct anilox means more than just going to a chart or using a supplier’s recommendations. Although these are great tools, to get consistent results day in and day out requires running banded roll trials taking into consideration all of the elements mention above. Collecting all the data from the trials will help in determining the correct lpi and volume, needed to print highend flexo products. Having the proper anilox is of central importance in transferring the required ink layer thickness and well documented cleaning procedures will help to maintain the cell volume in a controlled manner. These are the key factors in selecting anilox rollers and maintaining quality print.

To view the original Converting Quarterly article click HERE.